Antistatic Solutions

Are you looking for a safer and more productive process without static issues? Read about our antistatic additives, antistatic agents, liquids and equipment.

A convenient overview of our antistatic solutions. Download our e-book

Equipment

Is there a build-up of static electricity during your production process?

Integrating antistatic equipment into your manufacturing line neutralises static energy on-the-fly without delay.

Additives

Is static build-up on your plastic packaging hindering your manufacturing processes for food contact or automotive applications?

Adding an antistatic agent to your extrusion process will provide an immediate antistatic effect.

Liquids

Are you losing time and quality due to static energy on surfaces and electronic workstations?

Our unique brand of (food-contact approved) liquid products facilitates surface treatment by spraying, soaking or padding.

Are you facing a specific antistatic challenge? Talk to one of our experts.

How we solve static problems

01. ANALYSIS

Do you have an antistatic issue but don’t know how to solve it? Have you heard of a solution but don’t know whether it’s suitable for your company?

We will discuss your case to pinpoint the exact issue.

02. TESTING

Depending on the issue and solution, we can test the antistatic agent on some of your samples or we can provide free samples of the antistatic products for you to apply yourself.

Either way, we provide a rapid service making sure your production is running at full speed as soon as possible.

03. FOLLOW-UP

Encountering issues with antistatic additives or liquids? We are on standby.

Call or email us. We will test the agents ourselves, find the problem and provide you with a working solution.

An antistatic solution, tailored to your industry

Plastic Industry

Untreated plastics are prone to static build-up. By neutralising the static current during processes (antistatic liquids) or getting ahead of the problem by altering the chemical composition of your products (antistatic additives or antistatic agents), you can eliminate unwanted static charges in your operations. This will prevent stickiness, jamming or mis-feeding.

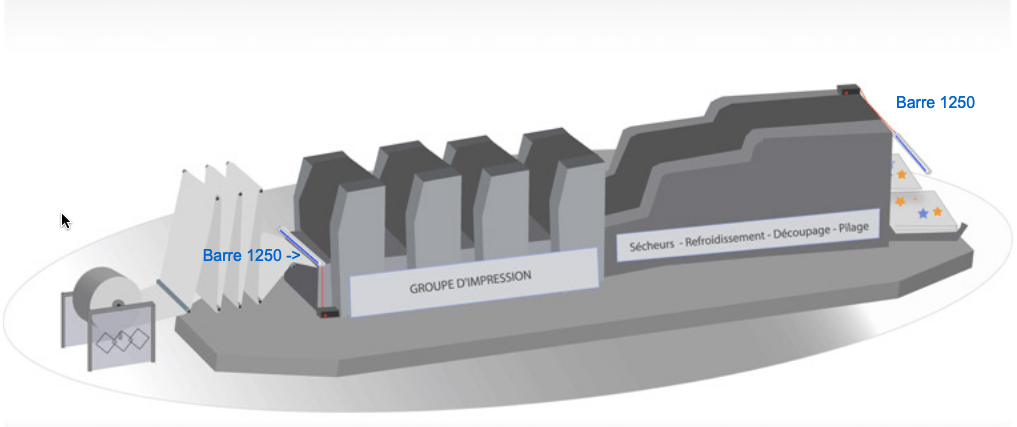

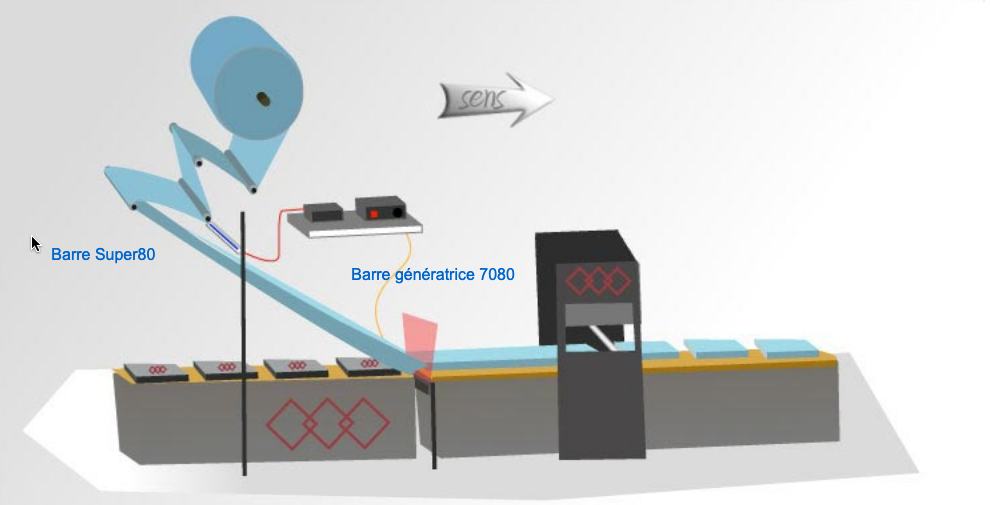

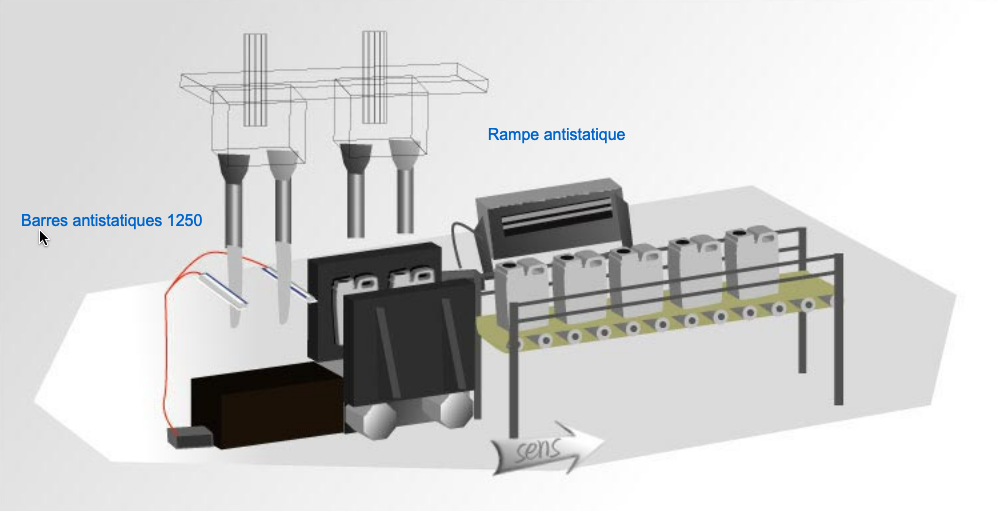

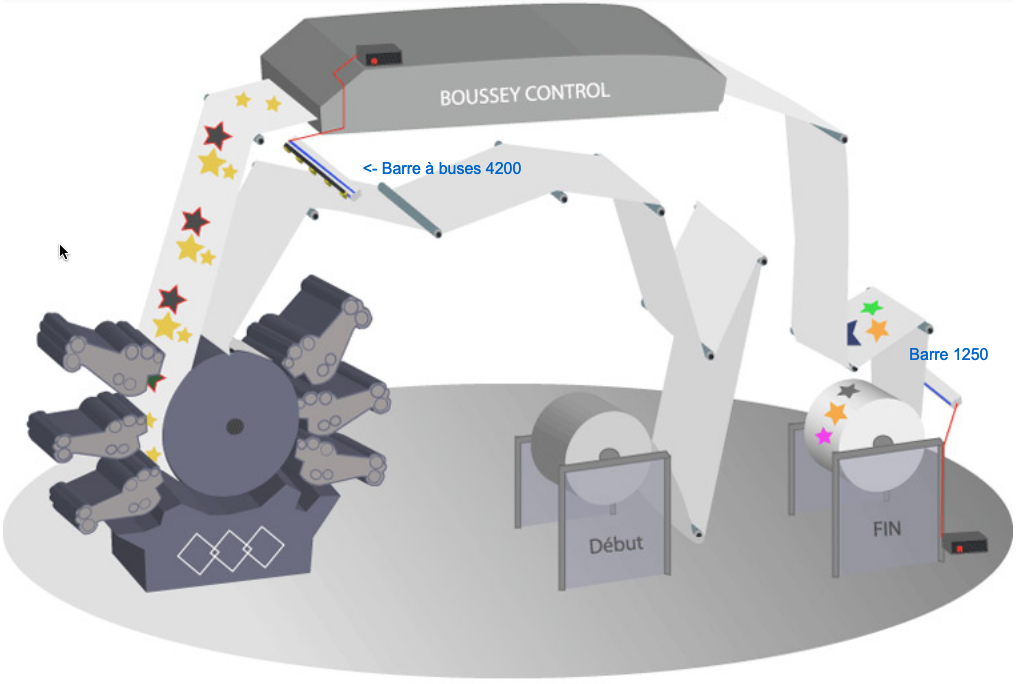

Printing Industry

High-speed printing results in an accumulation of static electricity. This can cause unexpected sheet behaviour, misprinting and fire-hazards during solvent processes. Integrating the right type of antistatic equipment in the right place in your production line will discharge static build-up before issues arise. The result is a smooth workflow and a safe and contamination-free process.

Automotive & aerospace

Electrostatic charges can have a severe effect on automotive procedures such as injection moulding, thermoplastics, blow moulding, paint spraying and so on. Ensuring a dust free and antistatic environment will reduce time and quality loss due to manual intervention. Antistatic solutions & agents also contribute to a safer manufacturing line for operators.

Our antistatic solutions

Is static electricity causing practical issues in your production process? Dust accumulation and stickiness during processing are common challenges for companies in both food and non-food industries.

The solution? Antistatic additives.

When using plastics for food or non-food applications, antistatic additives are added to the process to reduce or remove static energy, such as with buckets (REACH*) or automotive parts.

In our wide range of additives with mid-term, long-term and even permanent antistatic performance, we can find a solution for each and every industry or application. Our products can be integrated into PP, Polyolefin, PVC or HDPE blends.

Across industries these antistatic agents result in among other things dust-free packaging and automotive interiors, buckets or other receptacles for food-related applications and smooth mould release processes.

Our additives have been helping companies in streamlining their production processes for over 20 years. Over this time we have accumulated a great deal of expertise on antistatic agents for various industries and applications.

*Food contact approved certification

- Contact approved

- Lasting

- Industry-specific

- Various blending options

In some production environments there is a need to manually discharge surface energy. Antistatic liquids form a practical method for managing static charges during various stages of processing.

These antistatic agents are used by applying the solution to the surface of the material (textile, leather, glass, etc.) to be treated by spraying, soaking or padding.

Possible applications may involve static dissipative tooling, packaging and clothing. Adding these antistatic agents will among others things offer dust-free materials on electronic work tables, clean room surfaces and general plastic surfaces.

- Manually applicable

- Surface treatment

- Food contact approved

- Application-specific

The build-up of static electricity can cause a loss in production speed and quality. The misbehaviour of materials, dust accumulation or mis-feeding are common indicators of an increase in static charges. In some environments there is also an increased risk of shock for workers along with fire hazards.

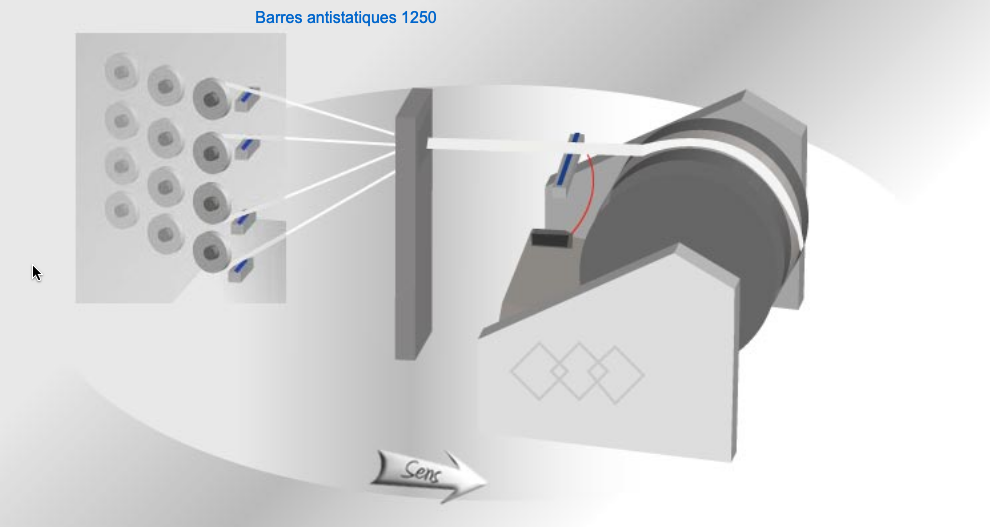

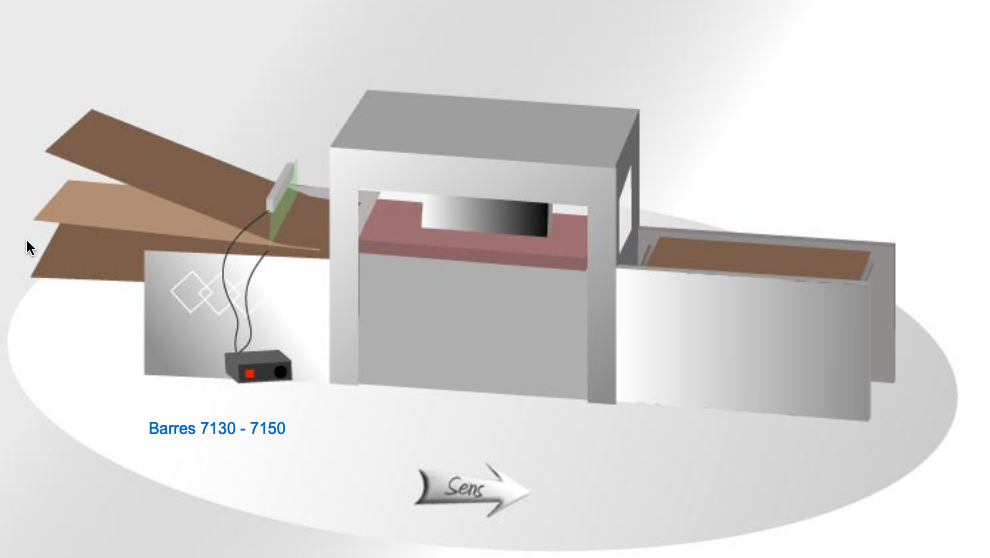

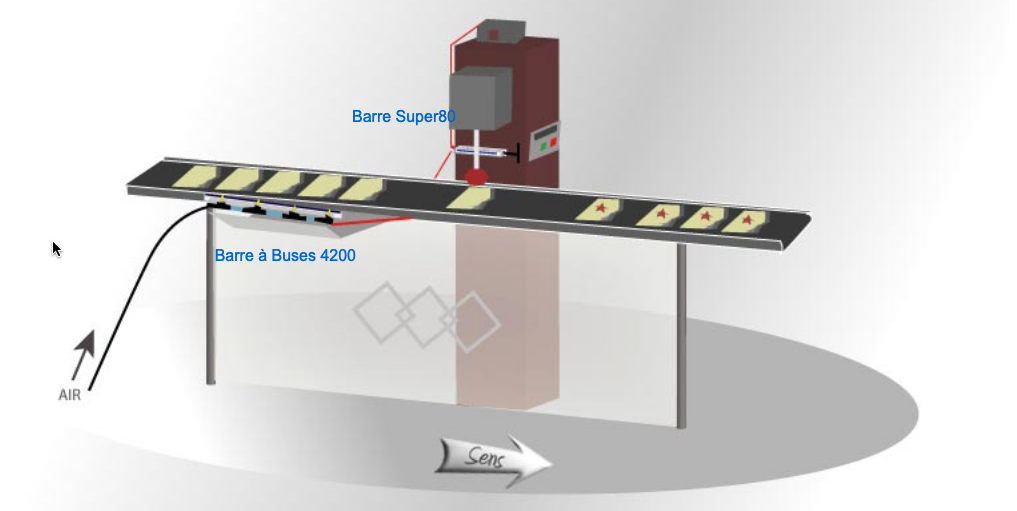

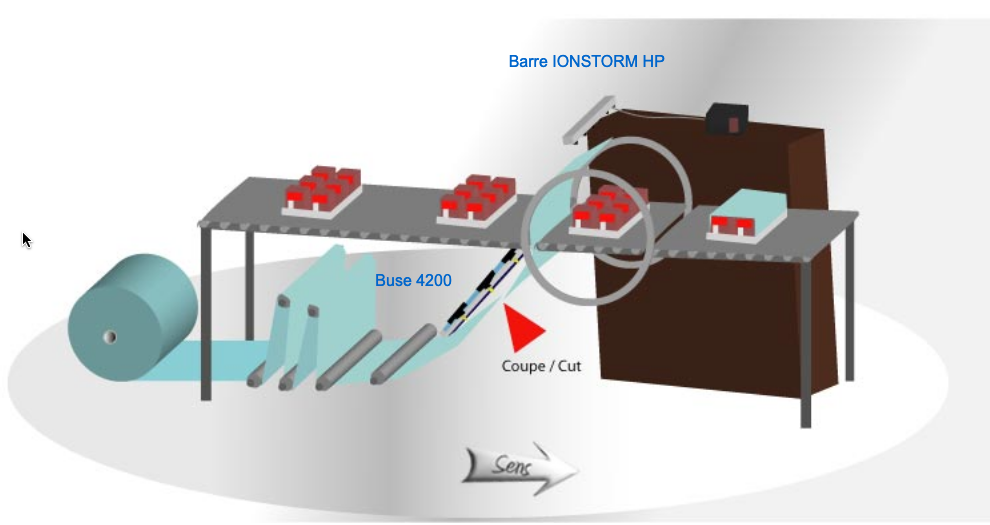

Integrated antistatic equipment reduces, eliminates or helps to control static electricity. By adding an antistatic station to your production line, static build-up is discharged while your process keeps running without delay.

- Cost-efficient

- No delay

- Operator-safe

- Production quality