Protect your production environment against dust accumulation and contamination.

- December 20, 2021

- 8:53 am

Are you experiencing severe dust accumulation in your work area? Does this contamination of your work area lead to useless products or prolonged production times? Are you losing a lot of time and money trying to solve these problems, without any luck? Discover our quick and easy solutions.

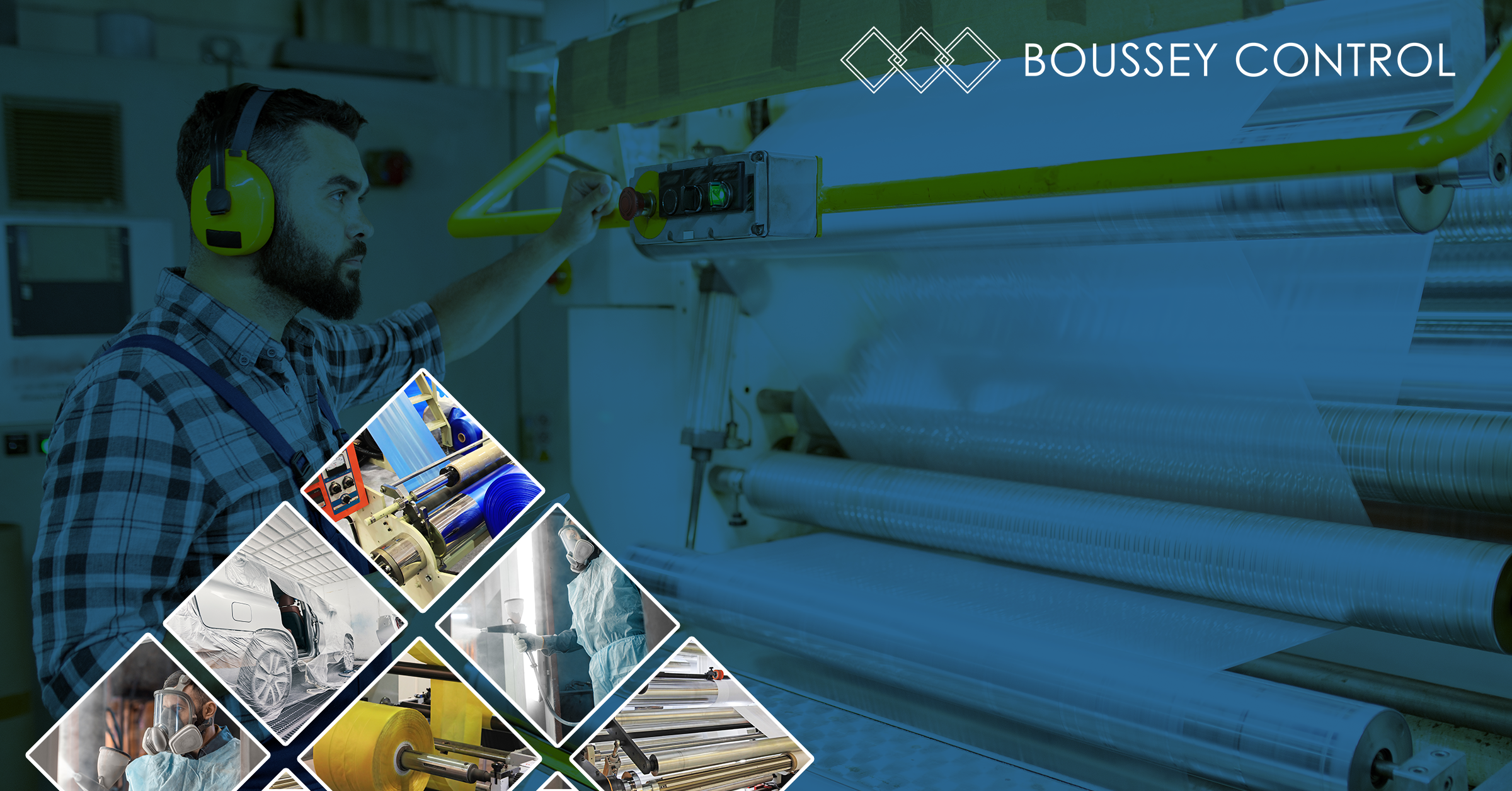

- Medical sector

- Industrial production

- Food production

Do you need help? Looking for a Boussey-Control Solution?

Challenge us with one of your problems. Our teams is ready to face them with pleasure.

Zero dust policy in the medical sector

All these dust and contamination related issues are due to static charge buildup. Static electricity is a common problem in many sectors, including the medical sector.

Static charge buildup has a large share in the pollution of medical components during the production process. The attraction of (dust) particles leads to contaminated products, mostly during the production of plastic components like optical lenses, pacemakers, implants,…

Solving these static electricity issues can lead to significant improvement of the production process and can reduce the production costs.

Create antistatic surfaces during cleaning

Antistatic liquids can facilitate all your work processes. It’s an easy way to treat production environments or dry work areas in the prevention of static charge buildup. These antistatic agents are used manually by applying the solution to the surface of the material.

One of the options is to use antistatic liquids in cleaning products. For example adding a bit of antistatic agent to the water while you’re cleaning the floor. By treating the floor with the product, this surface in your work area won’t longer be statically charged and will reduce dust accumulation.

It’s also possible to treat electronic work tables or general plastic surfaces by simply spraying the antistatic liquid on the surface. Products can be treated by soaking it in the antistatic agent.

Food contact approved

It goes without saying that strict standards apply in the production or storage of foodstuffs. It’s of great importance to prevent contamination in this work area. However, keeping dust from gathering on your (plastic) materials can become quite a strenuous undertaking in large work environments. The AS90 liquid is food contact approved which means they can be used in foodstuffs or products to store any kind of food.

Service oriented partner

Depending on the issue and solution, Boussey-Control can test the antistatic agent on some of your samples or provide free samples of the antistatic liquids for you to try out yourself.

Either way, Boussey Control provides a rapid service making sure your production or work process is running at full speed as soon as possible.

Challenge us with your dust or static charge problems so we can look for the ideal solution, 100% adapted to your industry and application. Get in touch.